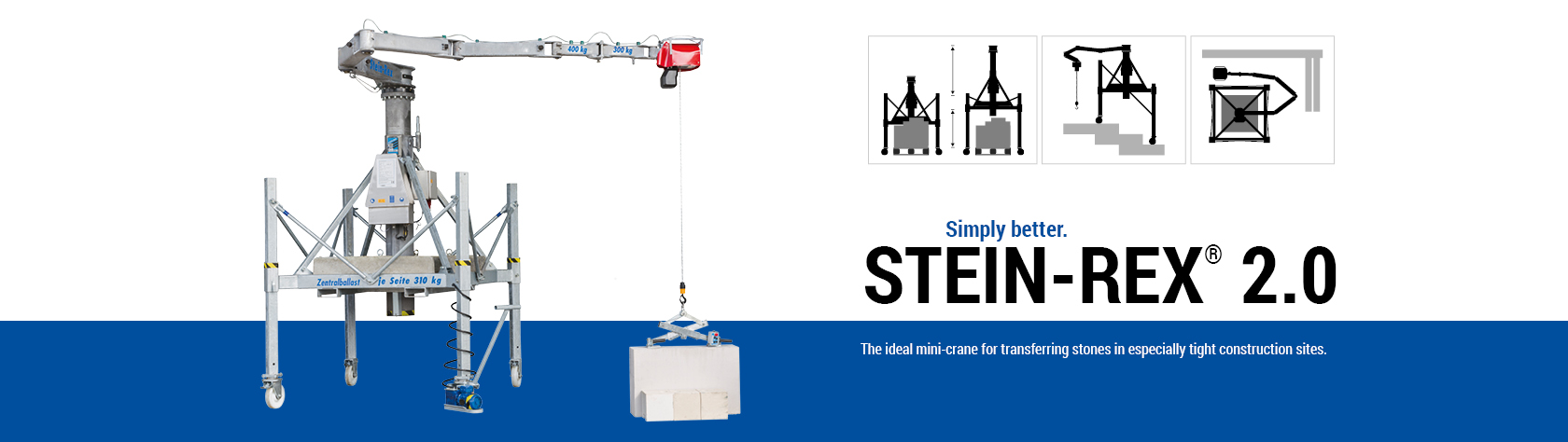

Stein-Rex® 2.0

Mini Crane systems for demanding construction sites

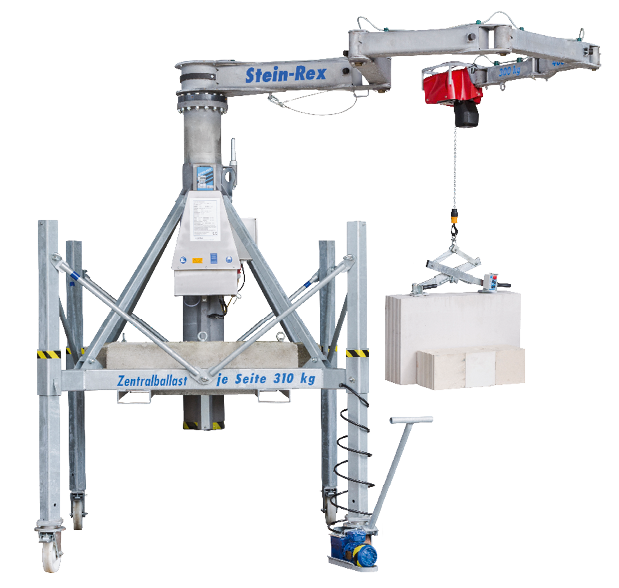

Tight space conditions on construction sites are often a challenge for both people and machines. Particularly when loads such as building bricks need to be lifted and transported to another point, large cranes quickly come up against their limits. Check out the new STEIN-REX® 2.0. Thanks to its intelligent design, the small crane with telescopable column and multiply articulated boom is ideally suited for restricted spaces. Schulte Transportsysteme GmbH has further developed its wall crane and made it even more stable and secure. The result: STEIN-REX® 2.0.

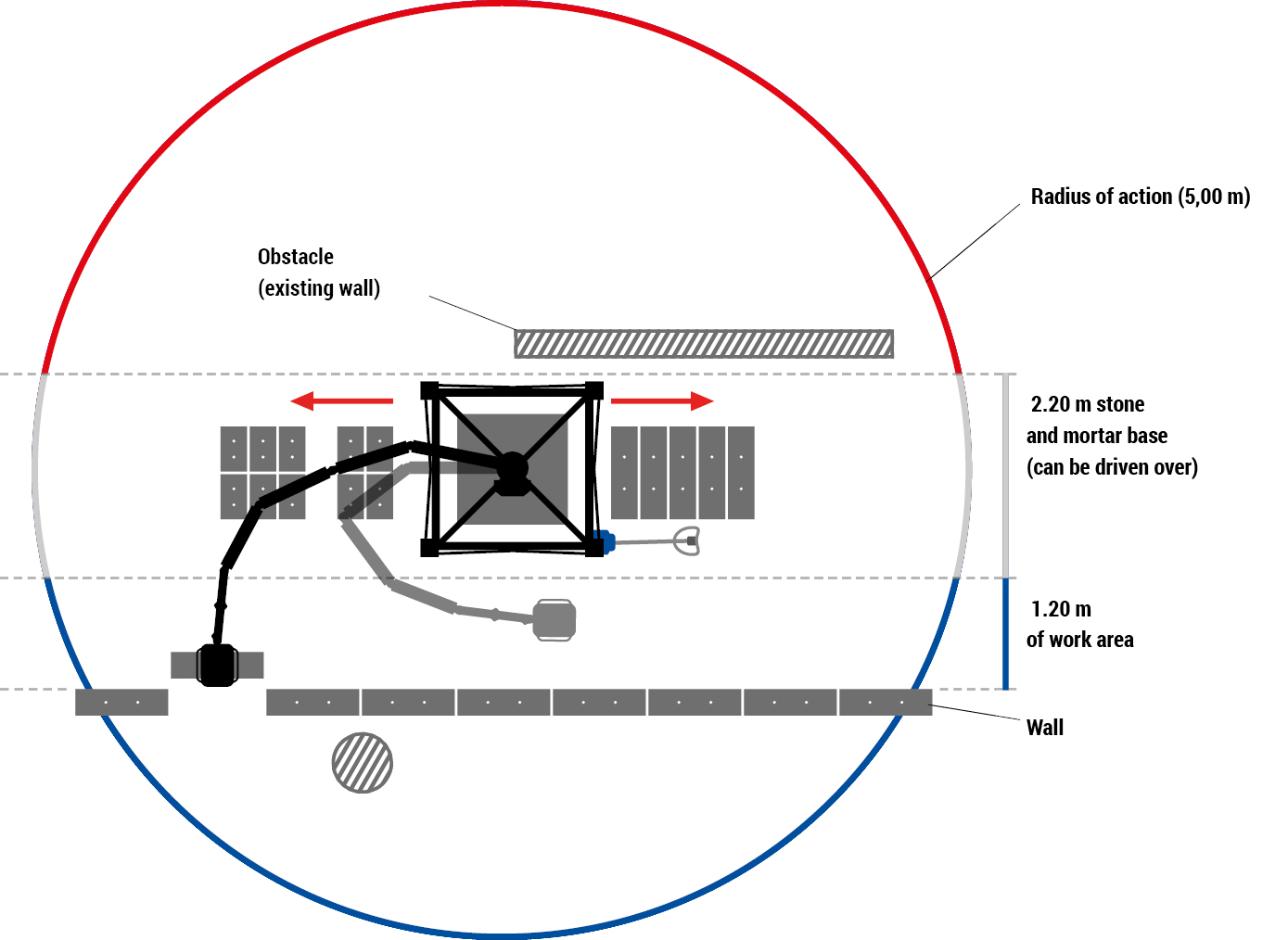

- Can be used in the most restricted spaces

- Obstacles can be passed over

- Smooth movement of bricks due to the multiply articulated boom and central ballast

- Gripper for any brick formats

- No danger area due to swivelling loads

- Can be adapted to any structural conditions

- Also stable when exposed to wind due to little surface area

- Excellent mobility due to electrical drive system with remote control

- Adjustable hook height

- With smooth start-up

- Easy transportation thanks to the small dimensions

Technical specifications

| Transport dimensions: | 2,20 m x 2,20 m x 2,35 m |

| Boom/load capacity: | 5 m / 300 kg; 4,3 m / 400 kg |

| Construction weight: | 1,2 t |

| Working weight: | 2,44 t |

| Transport dimensions central ballast: |

4 blocks at 310 kg 2 disposable pallets (1,0 x 1,0 x 0,5 m) at 640 kg (total: 1280 kg) |

| Control: | radio-controlled (chain hoist/telescope/drive) |

| Tower: | hydraulically telescopable |

Free consultation

One crane – numerous possibilities

Height-adjustable base frame

Manoeuvring in restricted spaces

In front of existing walls

Simply better.

WHAT DISTINGUISHES THE STEIN-REX® 2.0 FROM THE STANDARD MODEL

The STEIN-REX® 2.0 is equipped with a PLC. Compared to circuit board controls, these offer the advantage that the operating status is constantly visualised by LED indicator lamps. The programmable logic control (PLC) complies with the latest state-of-the-art technology and has proven successful internationally.

Overvoltages may occur at construction sites every now and then and lead to failures which disturb and endanger the entire workflow. Thanks to the built-in isolating transformer, such scenarios are avoided when using the STEIN-REX® 2.0. The small crane is thus protected against overvoltages.

Not only the telescopic column of the STEIN-REX® 2.0 is hot-dip galvanised, but also the multiply articulated boom. Therefore, it cannot corrode and is more durable. Additionally, the STEIN-REX® 2.0 has a hot-dip galvanised base frame.

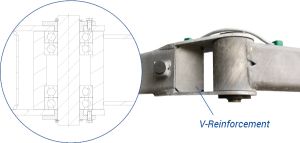

The diagonal braces on the driving carriage of the STEIN-REX® 2.0 provide for extra stability. Thanks to this construction, the small crane is additionally supported.

The double bearing of the boom articulations extends the service life of the STEIN-REX® 2.0.

The frequency-controlled drive of the STEIN-REX® 2.0 has a steel casting gear, which provides for more robustness and longevity.

In order that the STEIN-REX® 2.0 remains fully operational during a failure of the radio control, it disposes of an emergency control which ensures trouble-free continued working in such cases. This saves time and costs.

By using the folding boom, the load-bearing capacity of the STEIN-REX® 2.0 can be increased from 300 kg to 400 kg. In this way, even heavier loads can be moved in restricted spaces.

Thanks to an integrated operating hours meter, the STEIN-REX®2.0 provides optimal maintenance intervals. You also profit from this when renting or leasing.

Passage and hook height

Brickwork heights of up to 4.31 m are possible with the stone grab Raptor!

Lower position, telescopic column retracted

Lower position, telescopic column extended

Centre position, telescopic column extended

Upper position, telescopic column extended

Model versions

The appropriate STEIN-REX® for every use

- Available in two variants: 3 Ph (400 V) or PH (230 V)

- Maximum operating comfort thanks to smooth start-up on all three drives with frequency converter and PLC

- Two velocities on the chain hoist for precise setting

- Two velocities on the hydraulics

- Two velocities on the drive

- Radio-controlled brick gripper

- All functions can be operated via radio control

- In emergency cases, a cable control can be used

- The specialist for generator operation or with difficult construction electricity supply due to simple contactor control

- Two velocities on the chain hoist

- One velocity on the hydraulics

- One velocity on the drive

- Radio-controlled brick gripper

- All functions can be operated via radio control

- In emergency cases, a cable control can be used

- The most economic STEIN-REX® with electrohydraulics

- Without drive – the STEIN-REX® is pushed manually

- Operation of the hydraulics via separate control cylinder

- Operation of the chain hoist via pendant control unit with spiral cable

- Chain hoist with two velocities

- Getting started with STEIN-REX®

- The most convenient possibility to utilise the advantages of the multiply articulated boom

- Without drive – the STEIN-REX® is pushed manually

- The telescopic column is extended and retracted via a manual pump

- Operation of the chain hoist via pendant control unit with spiral cable

- Chain hoist with two velocities

Spare Parts

With regard to the supply of spare parts, two factors are of particular importance: speed and quality. With Schulte Transportsysteme, you can rely on both. All spare parts are immediately available from stock and are also present in our service cars. This will save you time and you can continue to work with the STEIN-REX® immediately. To make it even easier for you, the spare parts are premounted in component assemblies. This will leave you with considerably less installation effort.

Your STEIN-REX® is well advanced in years? We provide you with spare parts for all models of the small crane system. Our portfolio also includes overhauled spare parts. You will be exclusively supplied with products of the highest quality - directly from the manufacturer.

We will be happy to take care of the conversion or retrofitting of your STEIN-REX®. The electrical PLC for example can be integrated into the small crane system subsequently. We offer economic renewal options for older models of the STEIN-REX® as well.

Your added value when using the Stein-Rex® 2.0.

Brick transfer devices are required on German construction sites for the transfer of stones weighing over of 25 kg. It can even be expected that this limit will be reduced to 15 kg in the future. The STEIN-REX® 2.0 is an intelligently designed mini-crane which can also be used on challenging construction sites. Thanks to its multiple articulated boom and the extendable column, it requires clearly less space than a transfer device with straight boom. The free space for the pivoting range of the ballast weight is not required and stone packages can be driven over. Further advantages of the STEIN-REX® 2.0 include its manoeuvrability and the possibility to be used in front of existing walls and on stairs.

The small crane's stone pincers can be used universally and, using appropriate attachments, is suitable for gripping various stones, such as large-size stones, medium-size stones, aerated concrete, honeycomb bricks, lime sand bricks, block stones, concrete precision blocks or high-density lime sand bricks. System wall elements can also be transported efficiently. With its articulated arm boom, the STEIN-REX® 2.0 is the ideal supporting tool in the field of masonry technology and stands out through its durability, robustness, corrosion-resistance and intelligent technology.

Free consultation

Our services

Purchasing ad part-exchange

Delivery & Maintenance

Introduction & Training

Repairs

Replacement parts

Servicing team

Telefonic consultancy

Checks acc. to VBG § 26